The Trusted Name in Temporary Storage

Get to know a new standard in efficiency and productivity with LeMar’s economical range of bunker storage products.

Customize the package that’s right for you from our exclusive hot-dip galvanized bunker wall frames, powerful aeration fans, heavy-duty tarps and robust pipe.

This is precision design for quick payback and unsurpassed quality and reliability.

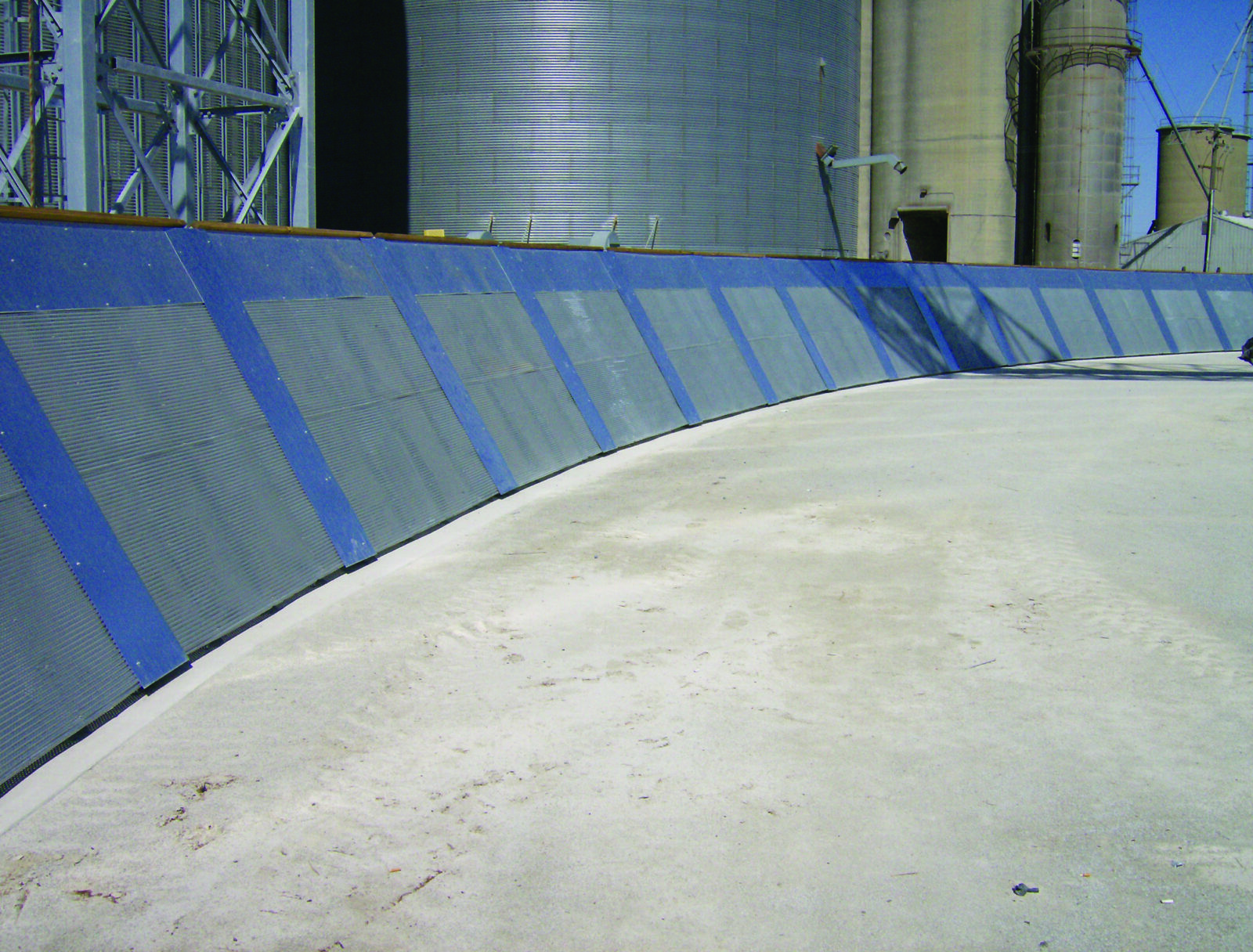

Choose from circular or oval bunker systems to meet any operation’s needs:

- Economical and easy to relocate or reconfigure.

- Exclusive stabilizer skid angle to keep walls straight and reduce wall slide.

- Galvanized corrugated wall sheeting.

- Hooded louvered opening for intake to eliminate plugged air holes.

Available Styles:

- 4′, 6′ and 8′ Galvanized Steel Walls

- Our wall frames are hot dip galvanized after fabrication. The walls are partly pre-assembled in 8′ sections. Each is securely anchored so no additional cabling is required.

- The hooded louvered openings (instead of perforations) are specifically designed to prevent blockage by grain kernels, dust and dirt in the walls and aeration plates on the tower. The unloading problems with ground tubes are eliminated.

- 10′ Galvanized Steel Wall

- We started with the 10′ wall in 1982, and the original wall is still up today. This wall is shipped completely knocked down and must be assembled on site. Because of the extreme pressure on this height of wall and the possibility of sliding out and overturning, we require that it be bolted to a concrete base.

Powerful Aeration Fans

Knowing aeration is the key to successful grain storage, particularly in a temporary grain pile. We designed our fans for maximum power and performance:

- Engineered to assure proper airflow.

- Negative air aeration systems.

- Custom designed for bunker size.

- Axial flow or centrifugal style.

Robust Pipe

We offer a full range of aeration pipe to meet any operation’s size and capacity needs:

- Poly and steel.

- 12- to 24-in. (304.8 to 609.6 mm) sizes available.

Heavy-Duty Tarps

Our durable tarps keep grain safely covered and sealed from the elements to offer optimum potential for high salability:

- Woven, reinforced polyethylene at 12/14 mils (0.305/0.356 mm)

- Additional woven polyethylene thicknesses, polyethylene string and vinyl covers available.

- Covering permanently affixed to frame top.

- Custom covers available to suit your needs.

Each aeration system is designed individually, based on the system’s size, grain depth, grain type and layout.

Full, round, perforated duct is laid on the floor of the system. The duct is connected to a centrifugal or vane axial fan located outside the system between the wall frames. Plastic, perforated air duct is laid over the top of the grain pile on a rectangular system at specified intervals to supply overhead intake of air under the tarp. Aeration fans are placed on a suction system, drawing intake air through the overhead plastic duct and through the sidewall and then exhausting it through the fans.

LeMar’s Commercial Center Tower Full Round Aeration System and Mini Temporary Grain Storage System deliver balanced aeration throughout the entire grain mass. These state-of-the-art systems push airflow through the entire grain mass without costly turning, for effectiveness similar to full floor aeration in upright tanks.

Perimeter walls allow outside air to enter evenly, and hooded louvered openings (instead of perforations) are specifically designed to prevent blockages on the walls and aeration tower.

Quick and Easy Cover Deployment

LeMar has come up with a quick and easy solution to attaching the bunker cover to the lift ring. Instead of using a double plate attachment system to attach the cover to the lift ring, we use snap hooks that are sewn into the cover at equal spacing. We then have a flashing that attaches to the upper part of the lift ring along with our tower skirts, giving you a fully enclosed tower that is weather resistant. Instead of taking a half day to attach your cover to the lift ring, it can easily be installed and ready for deployment in less than an hour.

Fast Return on Investment

LeMar’s Temporary Commercial Grain Storage System, including the base construction, means warehousing can offer a short-term payout. With uncertainty as to what government programs or market carry will offer in the future, this initial investment in temporary grain storage is a distinct advantage to your bottom line now and for years to come.

The aeration tower, conveyor with truss and distribution box are designed and factory welded to be hoisted into place at the job site and quickly bolted together with minimal welding. The all-steel aeration rests at a 30-degree angle to prevent adverse weather infiltration that could block air entry. Wall height of 48 to 120 inches (121.9 to 304.8 cm) allows plenty of surface area for balanced airflow while facilitating easy tarp tie down.

The grain pile is covered with a reinforced poly tarp. Typical thickness is 12- or 14-mil woven or 6- or 8-mil string reinforced polyethylene. Custom tarps and mil thicknesses are available to meet individual needs and requirements.

Standard Tarp

The standard LeMar 12- or 14-mil reinforced polyethylene sheeting is manufactured through the use of a weaving process. First, narrow ribbons of high-density polyethylene film are woven into a durable cloth. Then, both sides of the cloth are extrusion coated with an impermeable layer of low-density polyethylene — black on one side with white on the other, or black on black. The white layer is designed to prevent heat buildup and condensation beneath the cover and contains special UV inhibitors to prevent premature aging. The black layer contains carbon black, which blocks light penetration and prevents damage from UV radiation. Finally, heat from the process permanently fuses the layers together, resulting in these versatile materials with superior resistance to tearing, stretching and puncture.

Economy Tarp

The economy 6- or 8-mil string reinforced polyethylene offers several advantages in different applications. With its 1000-denier polyester yarn, the Integra SRP series offers excellent tear strength at the yarn, and the open areas between the yarns provide outstanding elongation properties. These physical characteristics make the Integra SRP the appropriate material for a wide variety of applications.

String reinforced materials are manufactured using a blend of the best polyethylene resins formed into two skins. These skins act as the “bread” to the reinforced “sandwich,” encapsulating a grid pattern of polyester yarn and a hot sheet of polyethylene to form a three layer product suitable for multiple applications. Once the raw goods are laminated together, the mill rolls are fabricated into custom-sized covers and liners. The finished panel is then rolled into a heavy-duty cardboard core and wrapped in a protective material for shipment.

Computer-assisted design and estimation lets us optimize performance and minimize per bushel storage costs on your storage requirements. We can quickly and accurately detail the most efficient and cost-effective system for your needs. Systems now in use range in capacity from 100,000 to 2 million bushels (3,524 to 70,478 cubic meters)